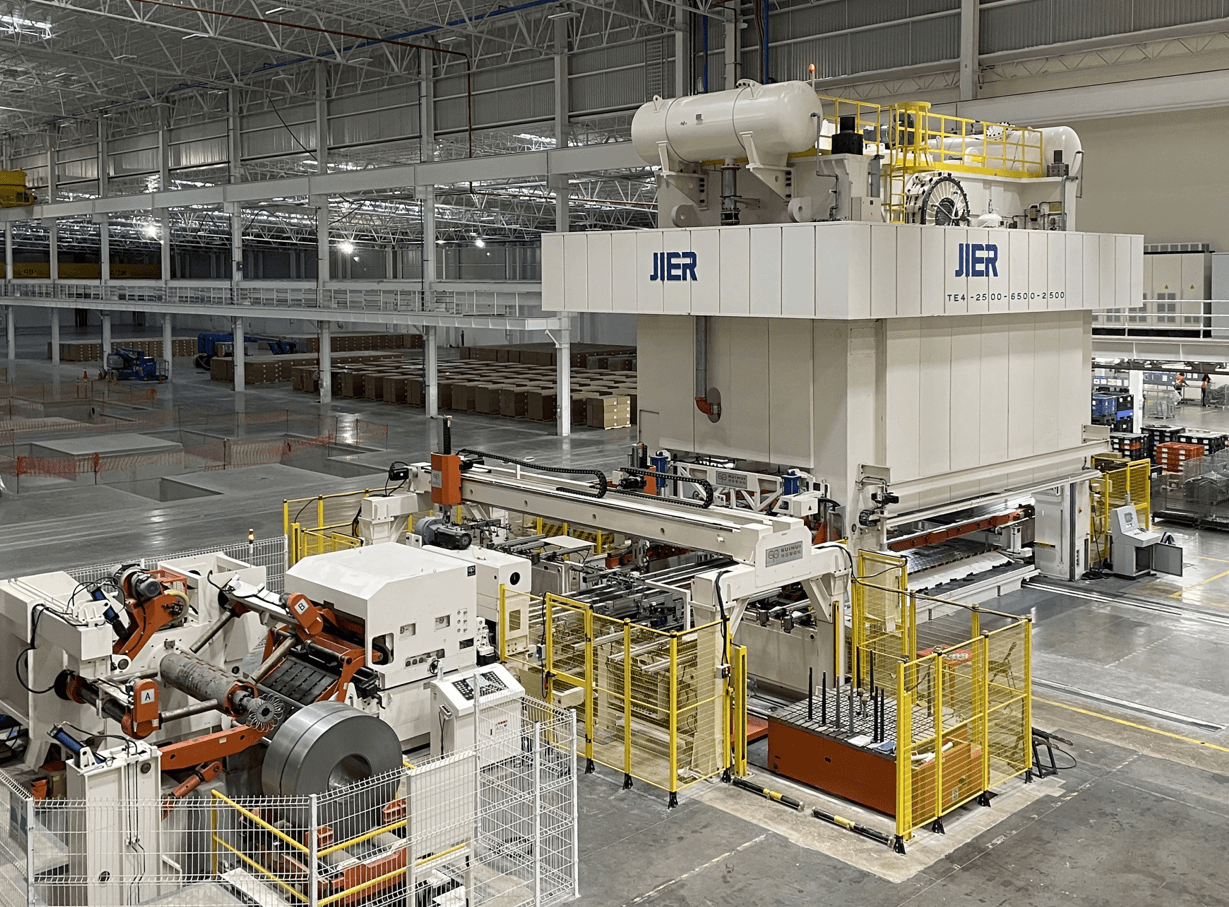

Smart Stamping Automation: A Key Component of Industry 4.0 Transformation

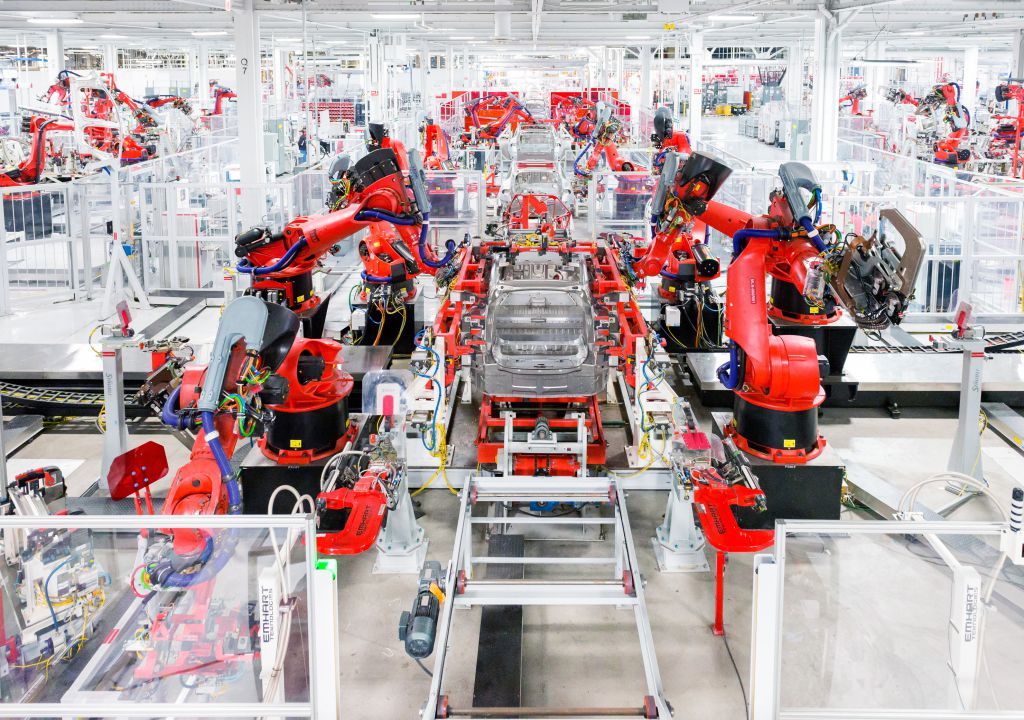

Industry 4.0, the fourth industrial revolution, is transforming the manufacturing landscape. This transformation is fueled by technologies like the Internet of Things (IoT), Artificial Intelligence (AI), and automation. One key component of Industry 4.0 is smart stamping automation, which is revolutionizing the stamping process. Stamping is a vital manufacturing process that produces high-quality, precise metal parts for a wide range